Construction is one of the most visible industries in terms of technology. With everything from skyscrapers to houses, construction constantly adapts to new and innovative ways of doing things. One area where this is especially evident is in the use of 3D printing. This technology has revolutionized the way buildings are constructed by allowing various designs and configurations to be created without the need for traditional tools and methods. In this blog post, we will explore the potential implications of 3D printing on the construction industry and its future. From reducing environmental impact to speeding up construction times, read on to learn more about how this cutting-edge technology is changing the game.

What is 3D Printing?

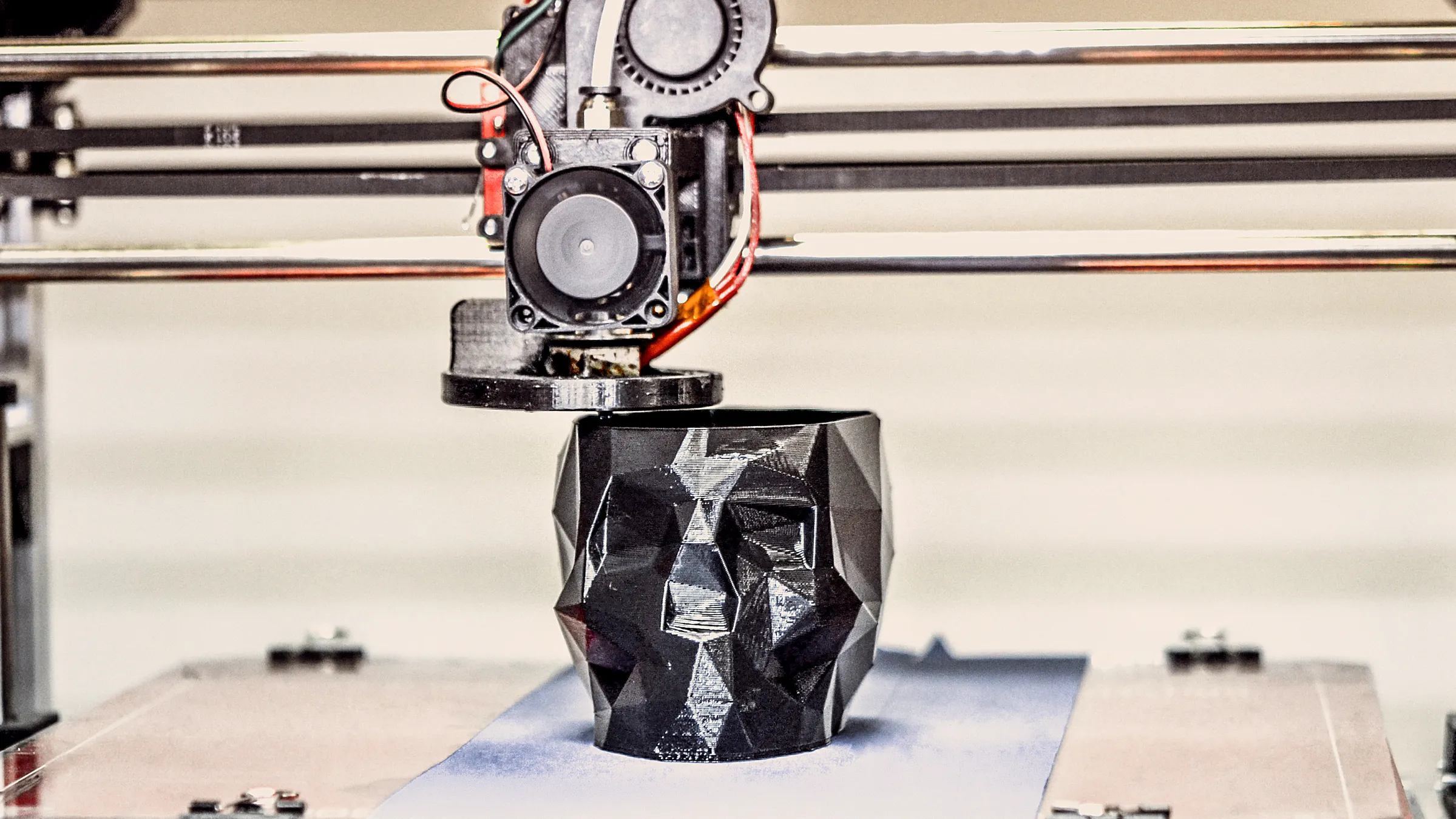

3D printing is a process of making a three-dimensional object from digital data. This technology has been around for many years, but it has recently become popularized by the emergence of 3D printers that can create objects from different materials.

There are two main types of 3D printers: desktop and industrial. Desktop 3D printers are typically smaller and more affordable than industrial 3D printers and are used to print small objects such as jewelry or figurines. Industrial 3D printers are larger and more expensive and are used to print large objects such as car parts or furniture.

One of the benefits of using 3D printing is that it allows for customization and personalization. You can easily create custom objects using standard software, which means that you can create items that are unique to you. Furthermore, because 3D printing is an additive process, you can create multiple copies of an object without building them from scratch. This makes it a great choice for products that need to be mass-produced, such as toys or clothing accessories.

3D printing is still in its early stages, so there are some limitations associated with this technology. For example, 3D printing processes tend to be slow, so they may not be suitable for applications where speed is essential (such as manufacturing). Additionally, because 3D printing relies on digital data instead of traditional materials like wood or plastic, it is not always possible to produce realistic results. However,

How is 3D Printing Used in Construction?

3D printing is a process where digital instructions are sent to a 3D printer to create an object from plastic, metal, or other materials. The technology has been used in manufacturing products for years, but it has recently been introduced into the construction industry.

One of the benefits of using 3D printing in construction is that it can save time and money. Instead of building an object from scratch, designers can use 3D printing to create a model of the object they need. This allows them to quickly and easily test different designs and find the best ones.

Another advantage of using 3D printing in construction is that it can speed up the process. If designers want to manufacture an object quickly, they can use 3D printing to create a prototype instead of waiting for a physical copy.

3D printing also has potential environmental benefits. Objects printed using this technology are usually lighter than traditional objects, which means they consume less energy when transported or stored. Additionally, because objects printed using 3D printers are usually made from recycled materials, they have the potential to reduce environmental waste overall.

The Advantages of 3D Printing in Construction

3D printing technology is quickly becoming a mainstream construction tool. Here are three reasons why you should consider using 3D printing in your next project:

1. Faster Construction Times

3D printing can help speed up the construction process by automating certain tasks, like creating detailed models of parts or assemblies. This can reduce the time needed to build a project, which can save money on costs such as labor and materials.

2. Reduced Waste

With 3D printing, you can create exact copies of objects, so there’s no need to waste any material during construction or renovation. This reduces the amount of waste that needs to be disposed of, further cutting costs.

3. Enhanced Design Flexibility

Conclusion

It seems hard to believe, but 3D printing is already changing the construction industry. By using digital models and printing layers of material one on top of the other, builders can create prototypes and scale models much more quickly and efficiently than ever before. Not only does this save time and money, but it also allows for designs that would never be possible with traditional construction methods. With 3D printing becoming increasingly accessible and widespread, it’s easy to see how this technology will play a decisive role in reshaping how buildings are constructed for years to come.