Pumps play a critical role in transferring liquids from one place to another. In some cases, the liquid being transferred may be hazardous or toxic, making it important to choose a pump that is safe and efficient. The canned motor pump is an innovative solution that meets these requirements, offering a number of advantages over traditional pumps.

What is a Canned Motor Pump?

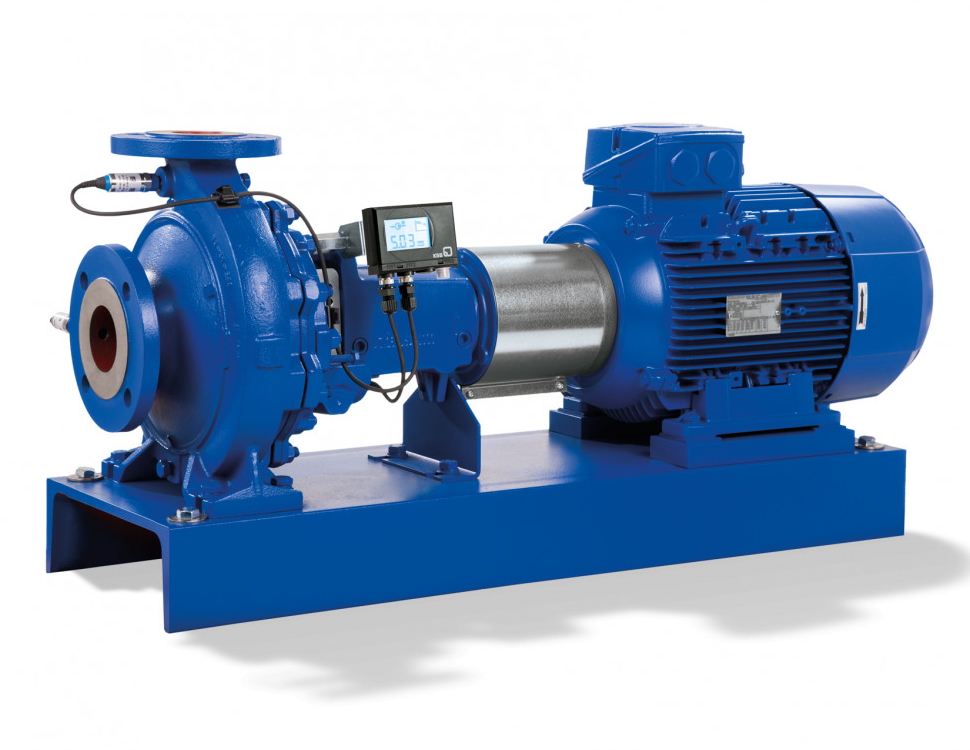

A canned pump is a type of centrifugal pump that features a unique design that eliminates the need for traditional shaft seals. The pump motor is contained within a sealed can that is submerged in the liquid being pumped. This design provides several key benefits, including improved safety and reliability, lower maintenance requirements, and reduced energy costs.

Benefits of Canned Motor Pumps:

Improved Safety:

- Canned motor pumps are ideal for transferring hazardous liquids because they eliminate the need for traditional shaft seals. This eliminates the risk of leaks or spills, which can be dangerous for both operators and the environment.

Reliability:

- Canned motor pumps are also designed to be highly reliable, with fewer moving parts and a simple design that minimizes the risk of mechanical failure.

Reduced Maintenance:

- Because canned motor pumps are sealed and have fewer moving parts, they require less maintenance compared to traditional pumps. This can reduce the costs associated with maintenance and repair, and increase uptime and productivity.

Energy Efficiency:

- Canned motor pumps are designed to be energy-efficient, with motors that are optimized for high performance and low energy consumption. This can help to reduce energy costs and improve the overall efficiency of the pumping system.

Canned Motor Pump the Ideal Solution for Hazardous Applications

Canned motor pumps are a type of centrifugal pump that has a completely sealed design, making them an ideal solution for handling hazardous fluids. The motor and the pump are integrated into a single, compact unit, eliminating the need for a separate pump casing and seals. This design makes canned motor pumps a preferred choice for applications where safety, reliability, and efficiency are of utmost importance.

The unique design of canned motor pumps makes them suitable for a wide range of industrial applications. They can handle fluids with a wide range of viscosities, temperatures, and pressures, making them an ideal choice for a variety of chemical processing, petrochemical, and pharmaceutical applications. The sealed design also makes them suitable for applications where leaks or spills could be harmful, such as the transfer of radioactive fluids.

Canned motor pumps are also known for their energy efficiency

The lack of external seals means that there is no leakage, which reduces the energy required to pump the fluid. Additionally, the integrated design means that there are fewer components to maintain and replace, reducing the cost and downtime associated with regular maintenance.

One of the key advantages of canned motor pumps is their safety. As the motor and pump are sealed within the same unit, there is no risk of fluid leakage. This means that there is no risk of fire or explosion, making them an ideal solution for applications where flammable fluids are being pumped. Additionally, the lack of external seals also means that there is no risk of exposure to toxic or hazardous fluids, making them a safer solution for workers.

In conclusion

Canned motor pumps manufacturers are a versatile and reliable solution for transferring hazardous liquids. With their unique design, they provide improved safety, reliability, and energy efficiency, making them an excellent choice for many industrial and commercial applications.